How to choose an axle?

Practical buyer guide

PHASE 1

View the tables

It is best to start by using the tables from page 21 to page 33 to identify the correct axle.

Thanks to them, by evaluating the load, the overhang, the configuration, the speed and the type of beam, you can identify the load-bearing structure for our axle.

PHASE 2

Contact us in case of doubts

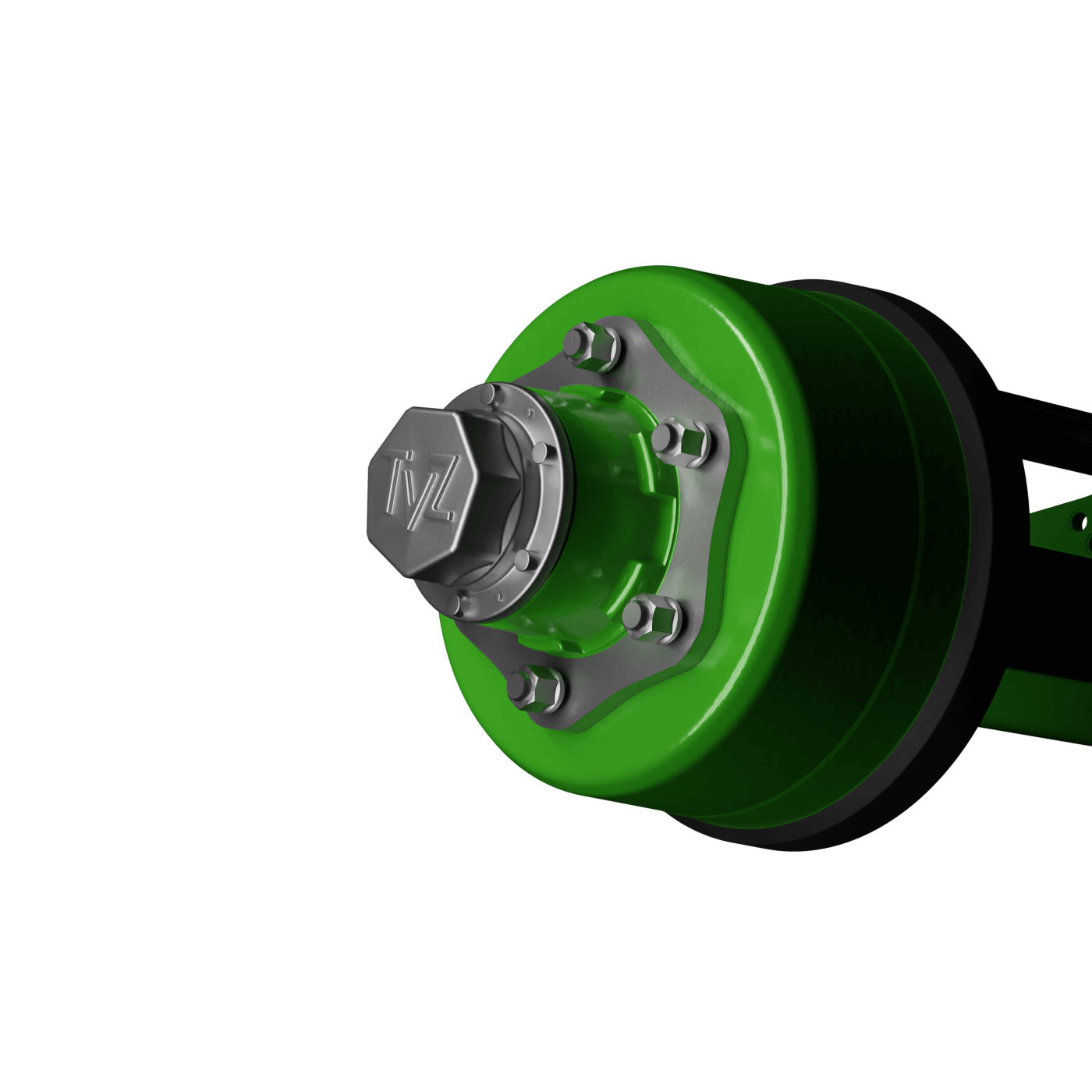

The loads indicated in the tables are the maximum permissible loads for the speed, the overhang and the indicated application. In addition, they refer to the use of wheels with a central flange (offset = 0) and with a tyre with a dynamic radius of less than or equal to 600 mm. For the use of wheels with non-zero displacements or dynamic spokes greater than 600 mm, it is advisable to contact our engineering department, which will be able to support you in this regard.

PHASE 3

Check the overhang

Once the axle has been chosen according to the capacity, check whether the referred overhang is also sufficient. The overhang is the measurement from the centre of the tyre to the centre of the axle fixing plate to the frame/suspension (height H). To do this, simply use the formula shown and explained before the capacity tables on page 20

PHASE 4

A practical tip

If the axles are going to equip a vehicle with the axles close to each other, we recommend the use of a self-steering axle (tandem vehicle) or two self-steering axles (tridem vehicle), so as to significantly reduce the axial force that would be generated by tyre drag on the ground during a curve. In fact, these forces overload the bearings, reducing their working life, and causing early tyre wear, which represents one of the largest vehicle maintenance expenses.

Use and maintenance

We provide the manual

We provide a practical manual to facilitate our product maintenance that includes a the spare parts catalogue, where you can easily find all the components to obtain maximum efficiency.